I. 目的

本次研究的目的是測試Brimrose AOTF-NOR光譜作為聚乙烯密度和熔體指數測量方法的可行性,計算兩個組分的預測標準誤差(SEP),并評估這是否是用于在線分析聚烯烴的化學和物理特性的方法。

II. 簡介

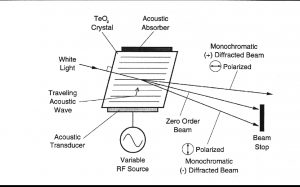

聲光可調濾波器(AOTF)的原理基于光在各向異性介質中的聲折射。裝置由粘在雙折射晶體上的壓電導層構成。當導層被應用的射頻(RF)信號激發時,在晶體內產生聲波。傳導中的聲波產生折射率的周期性調制。這提供了一個移動的相柵,在特定條件下折射入射光束的部分。對于一個固定的聲頻,光頻的一個窄帶滿足相匹配條件,被累加折射。RF頻率改變,光的帶通中心相應改變以維持相匹配條件。

光譜的近紅外范圍從800nm到2500 nm延伸。在這個區域最突出的吸收譜帶歸因于中紅外區域的基頻振動的泛頻和合頻。是基態到第二激發態或第三激發態的能級躍遷。因為較高能級躍遷連續產生的概率較小,每個泛頻的強度連續減弱。由于躍遷的第二或第三激發態所需的能量近似于第一級躍遷所需能量的二倍或三倍,吸收譜帶產生在基頻波長的一半和三分之一處。觸簡單的泛頻以外,也產生合頻。這些通常包括延伸加上一個或多個振動方式的伸縮。大量不同合頻是可能的,因而近紅外區域復雜,有許多譜帶彼此部分疊加。

現在,NIRS被用作定量工具,它依賴化學計量學來發展校正組成的參照分析和近紅外光譜的分析的關聯。近紅外數據的數學處理包括多元線性回歸法(MLR)、主成分分析法(PCA)、主成分回歸法(PCR)、偏最小二乘法(PLS)和識別分析。所有這些算法可以單獨或聯合使用來得到有價值組成的定性描述和定量預測。

III.? Methodology

本研究使用了121個已知熔體指數和密度值的低密度聚乙烯樣品,使用帶旋轉杯部件的Brimrose自由空間光譜儀收集光譜,對樣品進行旋轉,以平均出樣品中的不同效應,如均勻性和顆粒大小差異。在1100nm和2300nm之間采集光譜,分辨率為2nm,每個樣品收集了100次掃描,這些掃描被平均成一個頻譜,每次讀取的數據采集時間約為3秒。 該光譜以吸收光譜模式收集,然后處理成為第一個導數,然后,將第一個導數數據導入化學計量軟件包”The Unscrambler” 和PLS1進行數據分析。

IV.Results

- Spectra

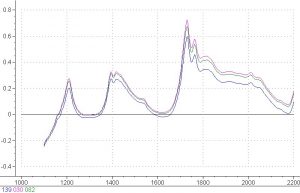

Figure 2.? Absorbance spectra of some polyethylene samples.

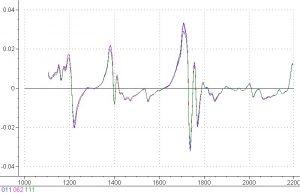

Figure 3.? First derivative spectra of some polyethylene samples.

2.????? Regressions and Modeling

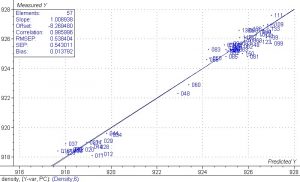

Figure 4.? PLS 1 regression model for density in polyethylene samples.

This PLS 1 regression plot for density in the polyethylene samples shows excellent correlation between the measured and predicted values.? The two distinct data sets in this plot are due to two different grades of material.? Samples 048 and 060 are two transition samples.? The data points create a good line of best fit and the correlation coefficient value of 0.985 is very high.?? The SEP is equal to 0.54, which proves that the model from this regression will be able to accurately predict density in polyethylene from spectral data.? The SEP is well within the standard deviation target value of 6%.

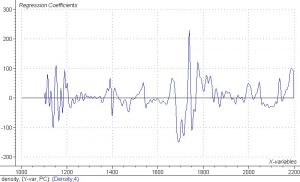

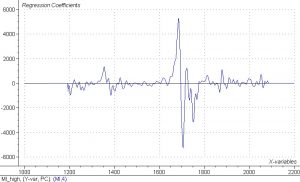

Figure 5.?? Regression coefficients for PLS 1 analysis of density in polyethylene samples.

The regression coefficients plot for the PLS 1 regression for density shows that most of the information for the regression comes from the wavelength regions from 1680nm to 1740nm.? This area corresponds to the first overtone of the C-H stretch and is the region where one would expect to see spectral changes corresponding to changes in density.? Density in polymers corresponds to changes in crystallization and this is what causes the changes in the spectral data.? The fact that the first derivative data shows the greatest amount of change in the wavelength regions from 1680nm to 1740nm confirms that changes in density can be quantified using spectral data from these wavelength regions and a calibration model.

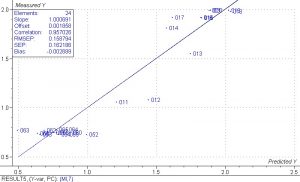

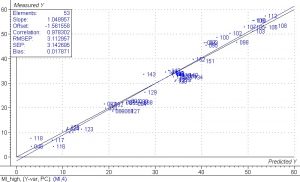

Because there was a wide range of values for melt index, it was decided to split the calibration for melt index into a low melt index calibration and a high melt index calibration.

The range of values for low melt index was from 0.7 to 2.0 and the range for low melt index was from 2.0 to 95.

Figure 6.? PLS 1 regression model for low melt index in polyethylene samples.?? SEP is equal to 0.16 and the correlation coefficient is equal to 0.957.

Figure 7.? PLS 1 regression model for high melt index in polyethylene samples.? SEP is equal to 3.14 and the correlation coefficient is equal to 0.978.

The results for these regressions show that it is quite feasible to measure melt index in polyethylene using spectral data.?? There was a 6% target for relative error and both the high and low melt index regressions were well within this value.? One high melt index sample had an extremely high value and was left out of the calculation as an outlier.

Figure 8.?? Regression coefficients for PLS 1 analysis of high melt flow index in polyethylene samples.

As was the case with density, the regression coefficients indicate that most of the information for the high melt flow index regression comes from the 1680nm to 1740nm wavelength range, which is the first overtone of the C-H stretch.? The small amount of noise in the regression coefficients indicates that there is no overfitting of the data.

| Parameter | SEP | Correlation Coefficient |

| Density | 0.54 | 0.986 |

Low Melt Index |

0.006 | 0.982 |

High Melt Index |

3.14 | 0.978 |

Table 1.? Summary of SEPs and correlation coefficients from PLS 1 regressions for density, low melt index, and high melt index in polyethylene samples.

V. Conclusions and Recommendations

This feasibility study has shown that the Brimrose Free Space spectrometer can be used to measure density and melt index in low density polyethylene.? The low value of SEP and the high value of correlation coefficients are well within the standard deviation of 6%.? Previous experience has shown that the use of local models in the case of melt index lowers the SEP even more.? These samples were measured in the laboratory using a rotating cup assembly and in-line measurement should show even better results.? Spectral rejection software developed by Brimrose will prove invaluable in this application.? This software will only average spectra when there is sufficient material in front of the window and will reject spectra when the amount of material is insufficient.?? A self-cleaning window will ensure that enough good spectra can be taken.? It is recommended that Brimrose install a spectrometer to conduct in-line tests of low density polyethylene which can be used to create a model that will allow for continuous in-line testing of polyethylene for density and melt flow index.