Flame Treatment Unit / belt conveyor GAS FLAMING N 火焰處理裝置/輸送帶輸送氣體

Characteristics

特點

Type:

類型:

belt conveyor

皮帶輸送機

Description

描述

To print on certain surfaces (in particular, plastics such as polypropylene, polyethylene and poly-acetate) may be necessary to subject the pieces, before (pre-treatment) or after printing (post-treatment), to a flaming process. This operation promotes the adhesion of the ink and its polymerization because it eliminates the superficial greasy substances and creates a temporary modification of the material surface, increasing its surface tension.

在某些表面上印刷(特別是聚丙烯,聚乙烯和聚乙酸乙烯酯)可能是必要的主題的作品,前(前處理)或印刷后(后處理),到一個燃燒的過程。此操作可促進油墨的附著力和聚合,因為它消除了表面的油膩物質,并創建一個臨時修改的材料表面,增加其表面張力。

There are several types of flamers: column, for lines, flaming belt. It is possible to install burners for LPG gas of different sizes depending on the surface to be treated (60-100-130-150-200 mm); they are fitted with flame non-return valves and made according to the EC regulations in force.

有幾種類型的產品:柱、線、燃燒帶。它可以安裝于待處理表面大小不同的液化氣燃燒器(60-100-130-150-200毫米);他們都裝有火焰止回閥,根據歐盟法規生效了。

The automatic control device allows to set the ignition of the flame, the detection of its presence, the gas solenoid valve.

自動控制裝置可以設置火焰的點火,其存在的檢測,氣體電磁閥。

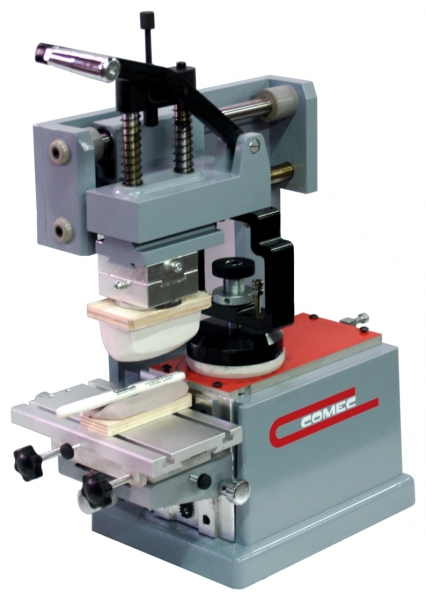

GAS FLAMING N

氣體燃燒

It is a flaming belt. The belt with the pieces flows through a frame on which are mounted the burners. A photocell detects the passage of the workpiece and activates the flame. The keyboard command allows you to adjust the speed of the belt. The belt is provided with gear motor.

這是一個燃燒的皮帶。帶件的皮帶通過一個框架,在該框架上安裝燃燒器。光電檢測工件的通道和激活的火焰。鍵盤命令允許您調整帶的速度。帶上齒輪馬達。

Flame Treatment Unit / belt conveyor GAS FLAMING N 火焰處理裝置/輸送帶輸送氣體