1、ID Multi-Roll Burnishing多輥拋光

The cold working action will improve minor surface irregularities and tool marks resulting in a low microinch surface finish.

-

Size Range: 0.157” (3.912mm) – 6.500” (165.1mm)

-

Application: Hole ID Sizing, Finishing and Hardening

-

Low Microinch Finish

-

Accurate Sizing

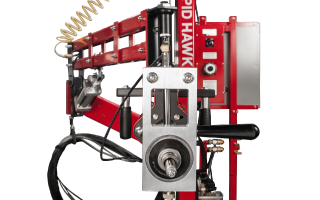

2、OD Carbide Roll Burnishing硬質(zhì)合金軋輥拋光

The versatility of these tools allows the burnishing of external diameters, tapers, radii, and face as well as large internal bores.

-

Part Preparations: 100-120 RMS

-

Feed Rate: 0.004”/0.008”

-

Speed: 400-800 SFM (1,200 Max)

-

Coolant Required: Water Soluble Or Oil

-

Low Microinch Finish

3、ID/OD Carbide Roll Burnishing(ID/OD硬質(zhì)合金軋輥拋光)

The boring bar style ID/OD tool is used on turning machines to burnish internal and external surfaces, creating extremely fine finishes in most ferrous and non-ferrous materials.

-

Part Preparations: 100-120 RMS

-

Feed Rate: 0.004”/0.008”

-

Speed: 400 – 800 SFM (1,200 Max)

-

Coolant Required: Water Soluble Or Oil

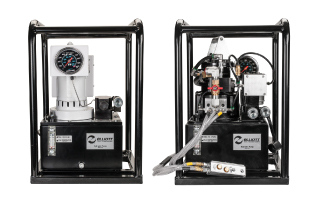

4、Diamond Burnishing金剛石拋光

Diamond burnishing tools with replaceable diamond stems are a low cost method to produce an ultra-smooth surface finish on linear surfaces.

-

Part Preparations: 100-120 RMS

-

Feed Rate: 0.003”/0.004”

-

Speed: 250 – 500 SFM (750 Max)

-

Coolant Required: Water Soluble Or Oil

-

-

-