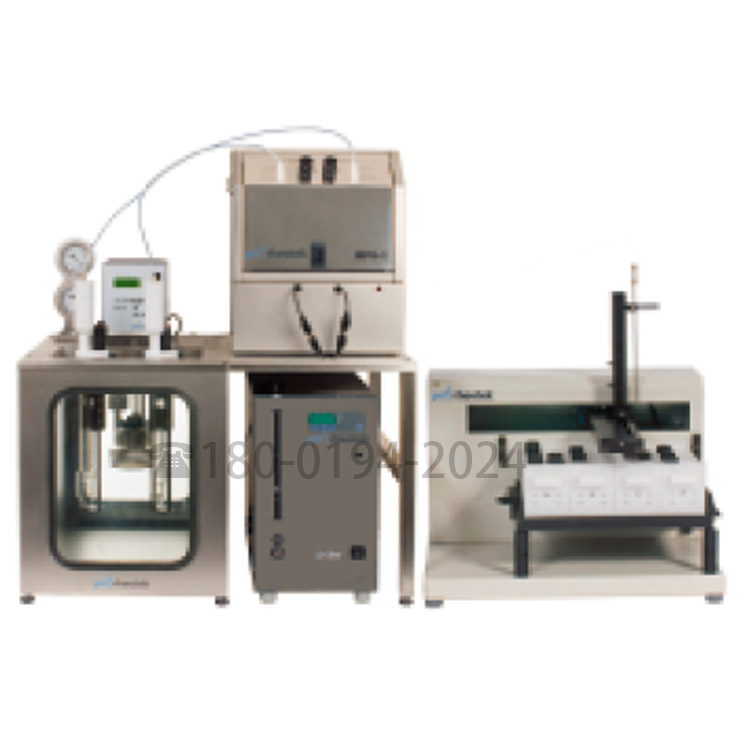

Two positions Auto PA polymer system PSL-Rheotek

RPV-1 (2) AutoPA

The PSL Rheotek RPV-1 (2) AutoPVC two position AutoPVC viscometer system is is configured specifically for fully automating the Reduced Viscosity of Polyamides (PA), nylon, dissolved in m-Cresol in accordance with ISO 307.

Auto systems fully integrate sample preparation, sample dissolution & sample loading, as well as flow time measurement, cleaning and reporting of results. One or two heating and stirring zones can be configured to control the dissolution of batches of samples. Both heating temperatures and stirring times are computer controlled and samples are cooled prior to being automatically loaded into the viscometer. Typical sample throughput is 6 to 8 samples per hour with two measuring positions.

The PSL Rheotek RPV-1 (2) AutoPA provides a reliable and precise system for measuring dilute solutions of polymers.

Auto systems not only combine the control of the sample preparation process but also the sample dissolution.

The RPV Auto system controls the heating and stirring times of polymer solutions, as well as cooling prior to

measurement.

Sample dissolution control is critical in order to ensure that polymer solutions, such as PA, do not degrade prior

to measuring their intrinsic viscosity.

The RPV-1 Auto automates the manual steps set out in standard methods, minimizing the variability of results.

Flow times are measured automatically using ASTM Ubbelohde viscometer tubes supplied with ISO 17025

certificates of calibration.

Cleaning is carried out in-situ utilizing solvents and a safe vacuum system.

The comprehensive RPV-1 Auto software program records all measurement data as well as calculating a wide

range of results.

Standard Practice:

ASTM D2857 Determination of the dilute solution viscosity of polymers.

Test Methods General:

ISO 1628 Part 1 Determination of the reduced viscosity, intrinsic viscosity and K-value of polymers in dilute solution using glass capillary viscometers

Test Methods Polyamides (PA):

ASTM D789 Determination of the Relative Viscosity of Polyamide (PA)

ISO 307 Determination of viscosity number Polyamides

DIN 53727 PA Bestimmung der Viskosit?t von L?sung, Polyamid (PA) in verdünnter L?sung.

Other Test Methods:

ASTM D445 Standard Test Method for determination of kinematic viscosity

ISO 3104 Petroleum products – determination of kinematic viscosity

IP 71 Section 1 Kinematic Viscosity

Typical RPV Applications And Configurations

Polymer Test Method Solvent Concentration Temperature RPV Measuring Positions

PA ASTM D789 Formic acid 8.4% 25°C 2 to 4

PA ISO 307 Formic acid 0.5% 25°C 1 to 4

PA ISO 307 Sulphuric acid 0.5% 25°C 1 to 4

PA ISO 307 M-Cresol 0.5% 25°C 1 to 4

Tube Type: AKV Ubbelohde

Part No. Ordering Information

RPV-1 (2) AutoPA PSL Rheotek AutoPA Polymer Viscometer – two positions complete with integrated sample preparation, sample heating and stirring block and Smart Sampler.

RPV-1 (2) AutoPA/D PSL Rheotek AutoPA Polymer Viscometer – two positions complete with integrated sample preparation, dual zones sample heating and stirring blocks with shared cooling system and Smart Sampler.

Part No. Options

RPVS010 RPV start up kit including glass vials (144 pcs) and plastic caps (500 pcs)

SIL-OIL Silicone bath oil

MIN-OIL Mineral bath oil

ACC-1 Anti-corrosive coating – required for sulfuric acid and DCA applications

TSC-1 Third cleaning option – required for sulfuric acid or custom applications.

SWC/U Split waste upgrade option

STATPACK RPV StatsPack extraction of results to PC or LIMS

特性粘度計,請聯系15821107090, 專業工程師為您提供解決方案