Machining head Kit 2000 加工頭包2000

Description

描述

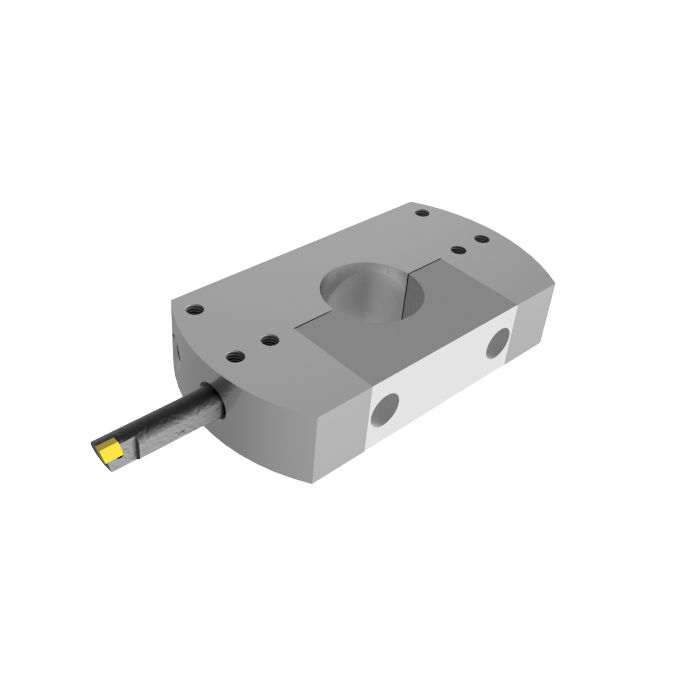

TOOLHOLDER HEAD FOR BORING AND FACING WITH RADIAL SEMI-AUTOMATIC FEED.

鏜面對徑向自動進給刀架頭。

Designed for the W Series Portable Boring Machine Tools. Proposed in various models of small, medium and large dimensions. Presents a high precision modular toolholder system for machining on various diameter ranges.

系列便攜式鏜機床設計。在各種型號的小型,中型和大型的尺寸。提出了一種在不同直徑范圍加工高精度模塊化刀柄系統(tǒng)。

The Kit 2000, is installed on the rotating axis of the machine tool, through a simple screw locking and without any interface.

該套件2000,是安裝在機床的旋轉軸,通過一個簡單的螺絲鎖定和沒有任何接口。

Possible special configurations, can be built and supplied upon request.

可能的特殊配置,可以建立和提供的要求。

This kit, evolving in the course of time in various models, with more refined, precise and balanced movements assures a major duration of the insert, a suitable cutting speed and the achievement of good surface finishing.

該試劑盒,在不同型號的過程中不斷發(fā)展,更精細,精確和平衡的動作,確保了一個重要的持續(xù)時間的插入,一個合適的切割速度和實現(xiàn)良好的表面處理。

FACING BOSSES

面對老板

SEEGER AND O-RING HOUSING

西格和O形圈的住房

EXTERNAL MACHINING

外加工

CIRCULAR POCKETS

圓形口袋

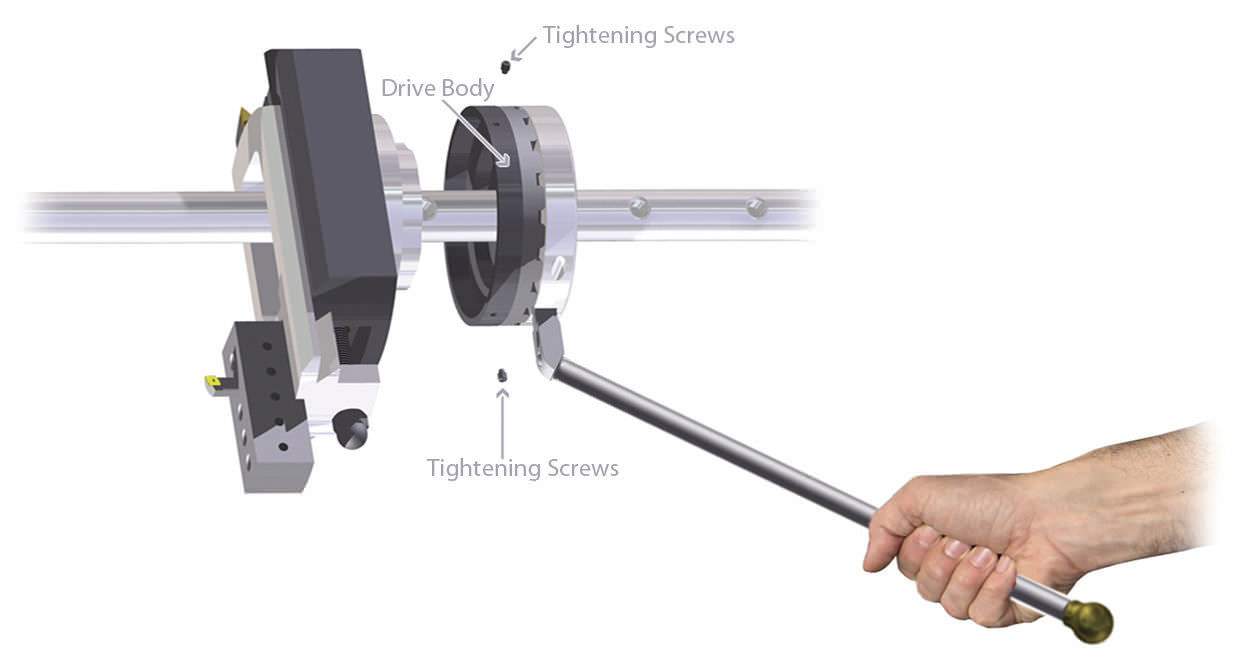

Actuator for Remote Operation for Kit 2000

用于遠程操作的執(zhí)行器2000

Through this mechanical device, it is possible to comfortably manage at a distance and in safety the “feed wheel” of the “Kit 2000″ allowing the operator to carry out and check the various stages of machining from any position and angle. Once installed, it acts as an actuator for the transmission of the radial forward motion of the tool;

通過這個機械裝置,它可以舒適地管理在一個距離,并在安全的“喂輪”的“包2000”,讓運營商進行,并檢查從任何位置和角度加工的各個階段。一旦安裝,它作為一個致動器的徑向向前運動的工具的傳輸;

the system is activated through a MODULAR COMMAND LEVER”. This system is equipped, inside, with a safety device that in case of jam or excessive strain of the tool, during the machining stage, it puts the transmission in neutral.

該系統(tǒng)被激活通過一個模塊化的命令桿“。該系統(tǒng)配有一個安全裝置,在該系統(tǒng)的堵塞或過大應變的情況下,在加工階段,它將在中性傳輸。

Machining head Kit 2000 加工頭包2000