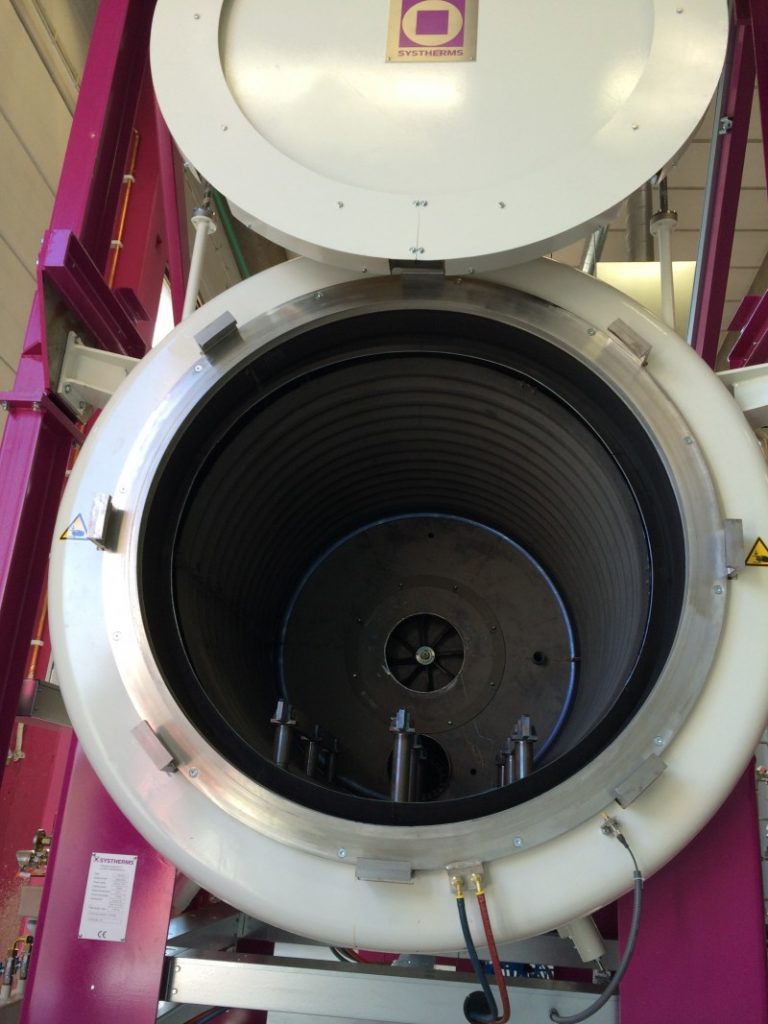

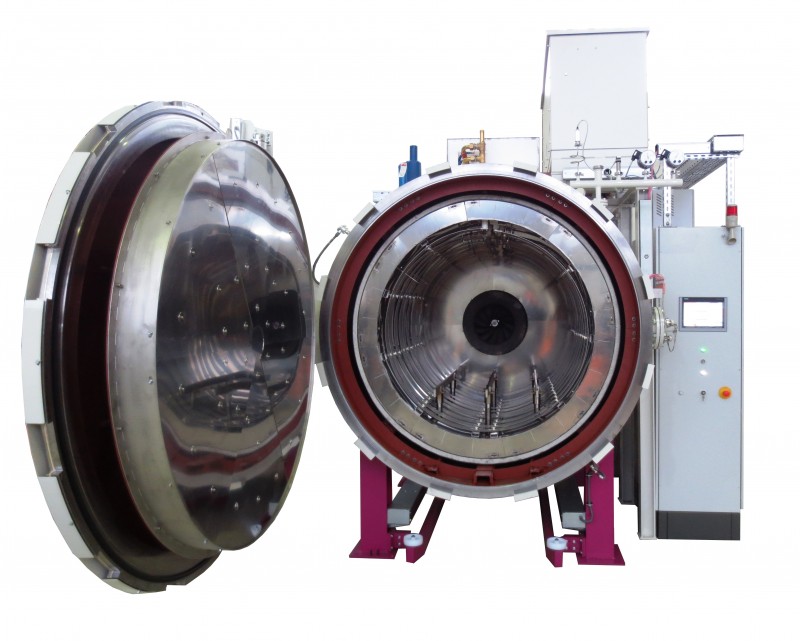

The furnace with bottom loading (bottom loader) is commonly used for round and heavy components. In principle, this type of furnace is a vertical VWC in which the load is positioned on the furnace bottom which can be lowered. The lowered furnace bottom can be driven by motor so that the batch can be loaded and unloaded by a hall crane.

Our vacuum furnace type VWS can also be used for a multitude of applications as for example low pressure carburizing, hardening, tempering, annealing and brazing.

The heat exchanger is either mounted above the heating chamber or in order to minimize the height in a separate housing beside the furnace vessel.

Advantages:

- optimum treatment of large rotation-symmetric components

- homogenous quenching with optional loading table rotation

- space-saving design possible with external heat exchanger

- high batch weights possible

- heating chamber in metallic design is possible

- uniform treatment results, even under most difficult conditions

- highest?temperature uniformity during heating and quenching

- heating and quenching characteristics according to your requirements

- complies with all current aviation standards (AMS 2750 E, NADCAP, etc.)

-

simple and secure control via touch screen

- proper control system “hestia”

-

different high vacuum options: oil diffusion pumps, turbo molecular pumps, cryo pumps

Standard sizes:

Type??????????????useable dimensions

????????????????????? (?xH in mm)

VWS 1010??? 1000 x 1000

VWS 1515??? 1500 x 1500

VWS 2020??? 2000 x 2000

Other sizes and technical details are available on request.