Researchers at University of Turin have developed cross-linked bio-derived cationic polymers from maltodextrin product to measure their water absorption capacity and water remediation capability as gel formation and nitrate, sulfate, and phosphate removal tests.

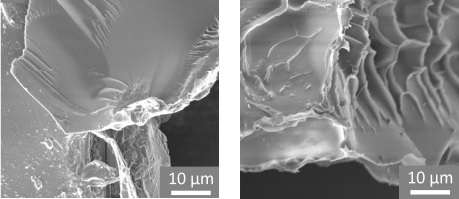

These polymers were comprehensively characterized via FTIR-ATR, TGA, DSC, XRD, SEM, elemental analysis, and zeta-potential measurements, to investigate their composition, and structure, along with other mechanical and chemical properties. For SEM imaging of the polymers, they were coated with a gold thin film of 12 nm with Vac Coat Desk Sputter Coater?DSR1, and the SEM imaging of the polymers before and after the water adsorption are as follows:

Subsequently, the water absorption capacity of the cross-linked polymers was measured ranging from 800% to 1500%, and water remediation tests for removal of common pollutants like nitrate, sulfate, and phosphate showed high sorption rates, with 80% of nitrates, over 90% of sulfates, and total phosphates removal.

Vac Coat offers various SEM coaters for deposition of metals or carbon for?SEM sample preparation?working at low or high vacuum conditions. DSR1 is a low-vacuum desk sputter coater commonly used for noble metal?sputtering deposition?to make the surface of SEM samples conductive.?DST1?with a turbomolecular pump, is capable of deposition of noble and oxidizing metals. Moreover, low and high-vacuum?DCR?and?DCT?carbon coaters can evaporate carbon fiber (thread) and carbon rods in a full/semi-automatic deposition process to prepare samples for SEM analysis. DSCR and?DSCT?hybrid coating systems merge the benefits of the sputter coaters and carbon coaters in one compact device, while?DSCT-T?adds the merit of?thermal evaporation?to the system.?DTE?and?DTT?coating models are ideal for the thermal evaporation of metals in a small or large chamber device, respectively.

Vac Coat also produces precise advanced research coating systems, such as triple target sputter coaters,?DST3?and?DST3-T, suitable for the deposition of multi-layers and alloys via co-sputtering.?DST2-TG?is another innovative Vac Coat product with double sputtering targets and a thermal source that can be fitted into a glove box through special feed-throughs.